Electric vehicles (EVs) are becoming increasingly popular as they offer a cleaner, more sustainable mode of transportation. However, working with an electric vehicle can pose unique challenges, particularly when it comes to the high-voltage components of the vehicle. In this article, we will explore what components of an electric vehicle are considered high voltage.

Components of an Electric Vehicle Considered High Voltage

Any component in an electric vehicle that operates at more than 60 volts DC is generally considered high voltage. The high-voltage components in an electric vehicle are critical to the functioning of the vehicle and include:

-

Battery Pack

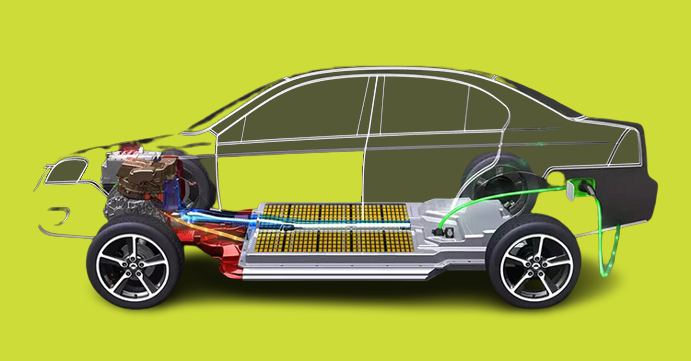

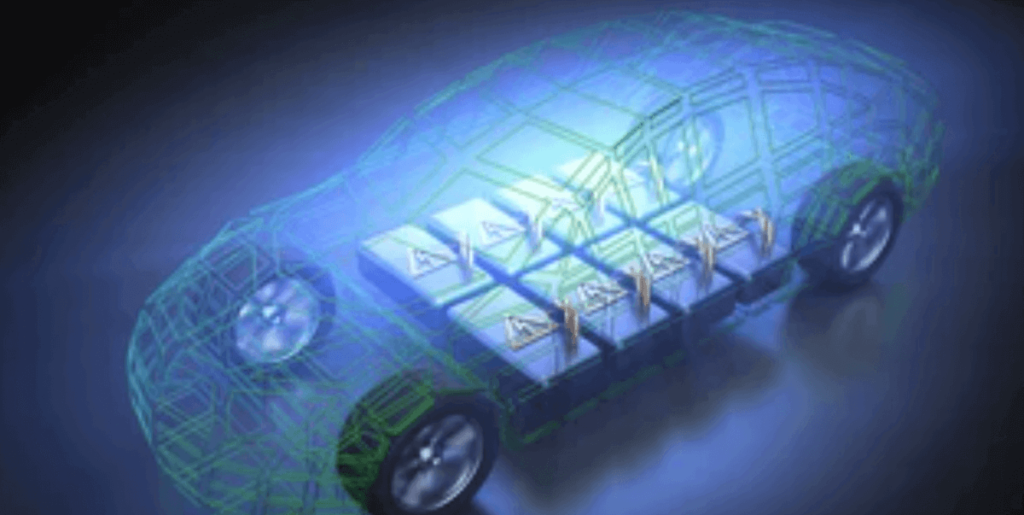

The battery pack is the heart of an electric vehicle (EV) and stores the energy that powers the vehicle’s electric motor and other high-voltage components. It is a critical component of an EV, as the performance and range of the vehicle depend heavily on the battery pack’s capacity and efficiency.

The battery pack typically consists of several individual battery cells that are connected in a series or parallel configuration to produce the desired voltage and capacity. The cells may be lithium-ion, nickel-metal hydride, or other battery chemistries, depending on the manufacturer’s preference.

The voltage of a battery pack can range from 200 volts for a small electric vehicle to over 800 volts for high-performance electric vehicles. The capacity of the battery pack is measured in kilowatt-hours (kWh) and determines the range of the electric vehicle. A higher-capacity battery pack will provide more range, while a lower-capacity battery pack will provide less range.

The battery pack management system (BMS) is an essential component that ensures the proper functioning and safety of the battery pack. The BMS monitors the voltage, temperature, and state of charge of each battery cell and manages the charging and discharging of the battery pack to ensure optimal performance and longevity.

The battery pack’s weight and size can significantly affect the electric vehicle’s performance and handling, and manufacturers must balance these factors with the desired range and capacity.

As EV technology continues to evolve, battery pack technology is improving to provide a longer range, faster charging, and lighter weight. The cost of battery packs is also decreasing, making electric vehicles more affordable and accessible to a broader range of consumers.

-

Electric Motor

An electric motor is the component of an electric vehicle (EV) responsible for converting electrical energy into mechanical energy to power the vehicle’s wheels. It is a critical component of an EV, as it provides the torque and power required to move the vehicle.

Electric motors used in EVs are typically brushless DC (BLDC) motors or AC induction motors. BLDC motors are more common in smaller EVs and have a higher power density, while AC induction motors are more common in larger EVs and have higher efficiency.

The electric motor operates at high voltage and is powered by the EV’s battery pack. The voltage of the electric motor can range from 200 volts to over 800 volts, depending on the manufacturer’s preference and the type of motor used.

The electric motor’s power is measured in kilowatts (kW), and it is essential to match the motor’s power to the vehicle’s weight and performance requirements. A higher-powered motor will provide faster acceleration and higher top speed, but it will also consume more energy and reduce the vehicle’s range.

The electric motor’s performance is also affected by factors such as temperature, humidity, and altitude, and manufacturers must account for these factors when designing the motor and the EV’s powertrain.

Regenerative braking is a feature of EVs that allows the electric motor to act as a generator and recharge the battery pack while slowing down the vehicle. This feature can improve the vehicle’s range and efficiency and is made possible by the electric motor’s ability to convert mechanical energy back into electrical energy.

-

Inverter

An inverter is an electronic device that is a key component in an electric vehicle’s (EV) powertrain. Its main function is to convert the DC voltage from the EV’s battery pack into AC voltage, which is required to power the electric motor.

In EVs, the inverter is typically a three-phase AC inverter that consists of power electronics, such as insulated gate bipolar transistors (IGBTs) or metal-oxide-semiconductor field-effect transistors (MOSFETs), and a control unit that regulates the output of the inverter. The inverter operates at high voltage, which can range from 200 volts to over 800 volts, depending on the manufacturer’s preference and the requirements of the electric motor.

The inverter is responsible for controlling the speed and torque of the electric motor, which is achieved by adjusting the frequency and voltage of the AC output. The control unit of the inverter uses feedback from sensors in the EV’s powertrain, such as the motor position and current sensors, to adjust the output of the inverter and optimize the electric motor’s performance.

Regenerative braking, a feature of EVs that allows the electric motor to act as a generator and recharge the battery pack while slowing down the vehicle, is also controlled by the inverter. The inverter can switch the electric motor from a motor to a generator to capture the energy that would otherwise be lost during braking and send it back to the battery pack.

The efficiency and reliability of the inverter are critical to the overall performance and range of the EV. Inverter efficiency is typically in the range of 95% to 98%, depending on the design and quality of the components used. The inverter must also be able to withstand high temperatures and operate in harsh environments to ensure the reliable and safe operation of the EV.

-

DC-DC Converter

A DC-DC converter is a component of an electric vehicle’s (EV) powertrain that is responsible for converting the high-voltage DC voltage from the battery pack to the lower voltage required to power auxiliary systems in the vehicle, such as the lights, audio system, and HVAC system.

The DC-DC converter is typically a high-frequency switching converter that consists of power electronics, such as MOSFETs or IGBTs, and a control unit that regulates the output of the converter. The control unit adjusts the output voltage of the converter to match the requirements of the auxiliary systems, which typically operate at 12 volts or 24 volts DC.

The efficiency of the DC-DC converter is critical to the overall performance and range of the EV, as any losses in the converter result in wasted energy that could otherwise be used to power the electric motor. The efficiency of DC-DC converters can range from 80% to 95%, depending on the design and quality of the components used.

The DC-DC converter must also be able to withstand high temperatures and operate in harsh environments to ensure the reliable and safe operation of the EV. Many DC-DC converters are designed to be water-cooled to maintain optimal temperature control.

The DC-DC converter is a critical component in an EV’s powertrain, as it enables the vehicle’s auxiliary systems to operate while also minimizing energy losses. Manufacturers must consider factors such as efficiency, reliability, and temperature control when designing the DC-DC converter to ensure optimal performance and safety of the EV. As EV technology continues to evolve, DC-DC converters will continue to improve, providing higher efficiency and reliability to enable greater range and performance.

-

Charging System

The charging system is a crucial component of an electric vehicle’s (EV) powertrain, responsible for charging the battery pack and ensuring that the vehicle has sufficient energy to operate.

The charging system consists of three main components: the onboard charger, the charging port, and the charging infrastructure.

The onboard charger is responsible for converting the AC voltage from the charging port into DC voltage to charge the battery pack. The charger is typically located within the vehicle and can have a power rating of up to 11 kW or more, depending on the manufacturer’s preference and the charging infrastructure’s capabilities.

The charging port is the physical interface between the EV and the charging infrastructure. It is typically located on the side or front of the vehicle and can support various charging standards, such as CHAdeMO, CCS, or Tesla’s proprietary Supercharger system. The charging port also contains safety features, such as locking mechanisms and interlocks, to prevent accidental disconnection or electrocution.

The charging infrastructure includes the charging stations and associated equipment, such as transformers and switchgear, that are responsible for delivering power to the EV. Charging infrastructure can range from public Level 2 chargers, which can provide up to 11 kW of power, to Level 3 fast chargers, which can provide up to 350 kW of power.

The efficiency of the charging system is critical to the overall performance and range of the EV. Charging efficiency can range from 80% to 95%, depending on the design and quality of the components used. The charging system must also be able to withstand high temperatures and operate in harsh environments to ensure the reliable and safe operation of the EV.

As EV technology continues to evolve, charging systems will continue to improve, providing higher efficiency and faster charging times to enable greater range and performance. Manufacturers must consider factors such as charging standards, power ratings, efficiency, and reliability when designing the charging system to ensure optimal performance and safety of the EV.

Safety Considerations

It is crucial to exercise caution when working with high-voltage components of an electric vehicle. The high voltage in these components can be dangerous and even deadly if not handled properly. Only trained professionals should work on high-voltage components, and it is crucial to follow the manufacturer’s safety guidelines.

In conclusion

high-voltage components are critical to the functioning of an electric vehicle. It is essential to understand what components are considered high voltage to ensure proper safety measures are in place when working with them. Electric vehicle owners should always consult trained professionals for any maintenance or repair work on high-voltage components.